Polyacrylamide (PAM) Flocculant – Powder & Emulsion

Polyacrylamide (PAM) is a high-efficiency water treatment agent widely used as a flocculant, coagulant, and dispersant in various industrial applications. Available in both powder and emulsion forms, PAM can be customized by molecular weight and ionic charge to suit different water treatment and processing needs.

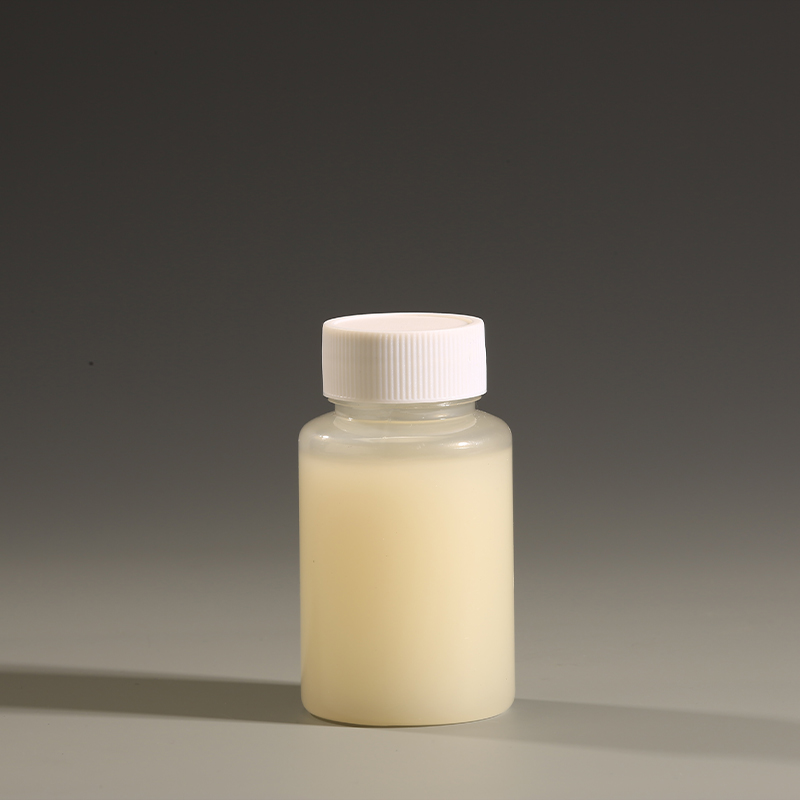

◆ Polyacrylamide (PAM) Powder

| Type | Cationic PAM (CPAM) | Anionic PAM (APAM) | Nonionic PAM (NPAM) |

|---|---|---|---|

| Appearance | White powder | White powder | White powder |

| Solid Content (%) | ≥88 | ≥88 | ≥88 |

| pH Range | 3 – 8 | 5 – 8 | 5 – 8 |

| Molecular Weight (×10⁶) | 6 – 15 | 5 – 26 | 3 – 12 |

| Ionic Degree (%) | Low / Medium / High | Low / Medium / High | Low / Medium / High |

| Dissolving Time (min) | 60 – 120 | 60 – 120 | 60 – 120 |

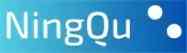

◆ Polyacrylamide (PAM) Emulsion

| Type | Cationic PAM (CPAM) | Anionic PAM (APAM) | Nonionic PAM (NPAM) |

|---|---|---|---|

| Solid Content (%) | 35 – 50 | 30 – 50 | 35 – 50 |

| pH Range | 4 – 8 | 5 – 8 | 5 – 8 |

| Viscosity (mPa·s) | 3 – 6 | 3 – 9 | 3 – 6 |

| Dissolving Time (min) | 5 – 10 | 5 – 10 | 5 – 10 |

Recommended Dosage: 0.025%–0.1%

Storage Temperature: 0–35°C

Shelf Life (Solid Form): 24 months

🌐 Application Fields

Municipal Water Treatment – Clarification and sludge dewatering.

Industrial Wastewater Treatment – Removal of suspended solids and oils.

Paper Industry – Used as retention agent, strength enhancer, dispersant, and for white water treatment.

Mining and Mineral Processing – Enhances sedimentation and separation processes.

Oil & Gas Industry – Used in enhanced oil recovery, drilling mud, and profile control.

Other Industries – Widely used in sugar processing, textile, dyeing, food processing, and juice production.